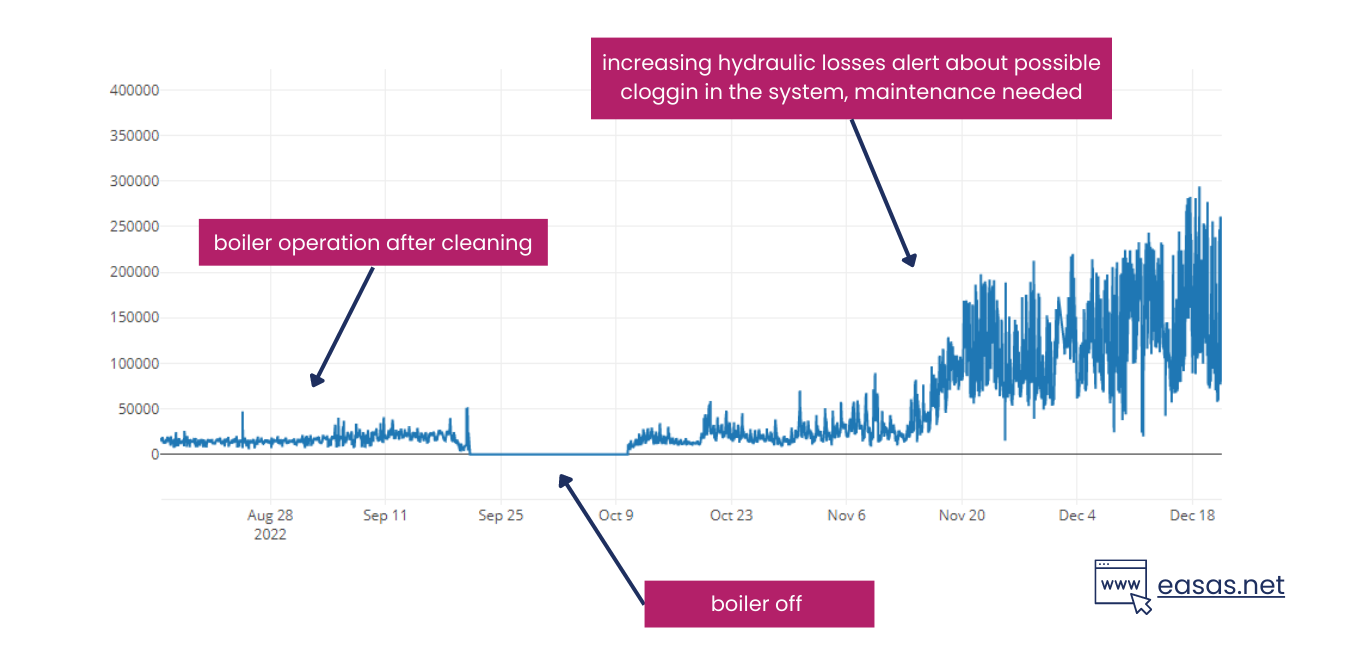

EA-SAS Boiler feature: Hydraulic losses calculation. Digital Twin functionality allow to continuously calculate hydraulic losses through flue gas path. Digital Twin involve live flue gas metered data also as flue gas mass flow from furnace estimated data.

Tracking of Hydraulic losses is mainly used for monitoring purposes during a long period of time. Increased hydraulic losses may indicate decreased heat exchange capability of a system as a result of clogging in the system.

EA-SAS Boiler is a Digital Twin and AI based solution designed to optimize Boiler Control through continuous calculation of boiler mass and energy balance also advanced automatic set points control. EA-SAS Boiler does not require additional investments to infrastructure.

EA-SAS Boiler as a service delivers 24/7 availability of Digital Twin solution without hardware changes and ROI less than 1 year.

What is the difference between Digital Twin and standard Control system (SCADA)?

Traditional control systems rely on data collection from equipment and PLC control logic, however human is responsible for Setpoint decision and change. Digital Twin together with Artificial Intelligent based algorithms deliver Setpoints to the PLC instead of operator. Optimized control Setpoints are delivered each minute, instead of humans with hourly delay.

Interested? Let’s talk,

Julius Samoska

WhatsApp / Mobile: +370 677 67695

E-mail: julius.samoska@energyadvice.lt

Find more about EA-SAS products for Predictive Maintenance here or visit easas.net.